Metal spinning is a well-known fabrication process that produces axially symmetric parts. This process is simple and yields high-quality results, and as such, it has become a primary production method for several manufacturers.

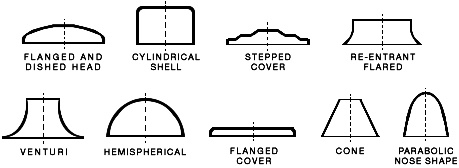

Metal spun parts have proven to be essential to various industrial and commercial applications. A wide variety of shapes and geometries can be achieved using metal spinning.

- Hemispheres and Spheres are highly versatile shapes. Hemispheres are frequently used in the lighting industry as decorative fixtures and in the communications industry as satellite dishes. Hemispheres can be welded together to create spheres, which provide the strength needed for demanding geological applications.

- Cones are used in applications that include alternate energy support and soil and concrete testing; in fact, two cones can be welded or soldered together to create slump cone funnels, which are required for concrete testing in the U.S.

- Flanged parts are crucial when producing diverse air calibration nozzles. The flanged shaped can be altered to accommodate

- Manufacturers utilize metal spun cylinders for different types of custom piping, tubing, and other products. These seamless cylinders are created using processes such as rolling, bending, and forming; these pieces are commonly used to create pressure vessels capable of withstanding high pressures.

- Reentrant spun metal pieces are easily identified due to their narrow shape. Reentrant-shaped pieces are primarily used in the food industry—applications include housing for pressure cookers and smokers, different cooking kettles, and individual soup cans. Metal spinning the most cost effective forming solution for this shape.

- The parabolic shape is frequently used in the communications industry. This metal spun shape is extremely conducive for accurate signal transmissions; antenna reflectors and satellite dishes are prime examples of parabolic products.

- Venturi metal shapes closely resemble hourglasses. These shapes are highly versatile; venturi pieces are used for dust collection in the power and bulk solids industry and spray painting in the automotive industry.

Different metal spun shapes are utilized throughout several industries, such as aerospace and defense, waste storage industry power, oil and agriculture, architecture, furniture manufacturing, HVAC, and many others.

Due to the assortment of shapes produced through this process, metal spinning is highly valued in both commercial and industrial applications.